Sublimation printing has revolutionized the way we approach personalized and custom designs. One of the most striking applications of this technology is sublimation printing on glass. This method is perfect for creating stunning visuals on glass surfaces, whether for decorative items, promotional materials, or personalized gifts. In this guide, we’ll explore everything you need to know about sublimation printing on glass, including the process, benefits, and tips for achieving the best results.

What is Sublimation Printing?

Sublimation printing is a process that uses heat to transfer dye onto materials. Unlike traditional printing methods that use inks, sublimation printing involves special sublimation inks that turn from a solid state directly into a gas without passing through a liquid phase. This gas then permeates the surface of the material, which in this case is glass, resulting in vibrant, long-lasting prints.

The Process of Sublimation Printing on Glass

Preparing the Glass Surface

Before you begin the sublimation printing process, it’s crucial to prepare the glass surface properly. The glass should be clean and free of any dust or oils that could interfere with the printing process. Use a glass cleaner and a lint-free cloth to ensure the surface is spotless.

Printing the Design

- Create Your Design: Start by creating or selecting a design that you want to print on the glass. Ensure that the design is in a high-resolution format to maintain clarity and detail.

- Print with Sublimation Ink: Use a sublimation printer to print your design onto special sublimation transfer paper. The printer will use sublimation inks, which are designed to turn into gas when heated.

- Transfer the Design: Place the printed transfer paper onto the glass surface, ensuring it is aligned correctly. The transfer paper is then pressed onto the glass using a heat press. The heat and pressure cause the sublimation ink to turn into gas and bond with the glass surface.

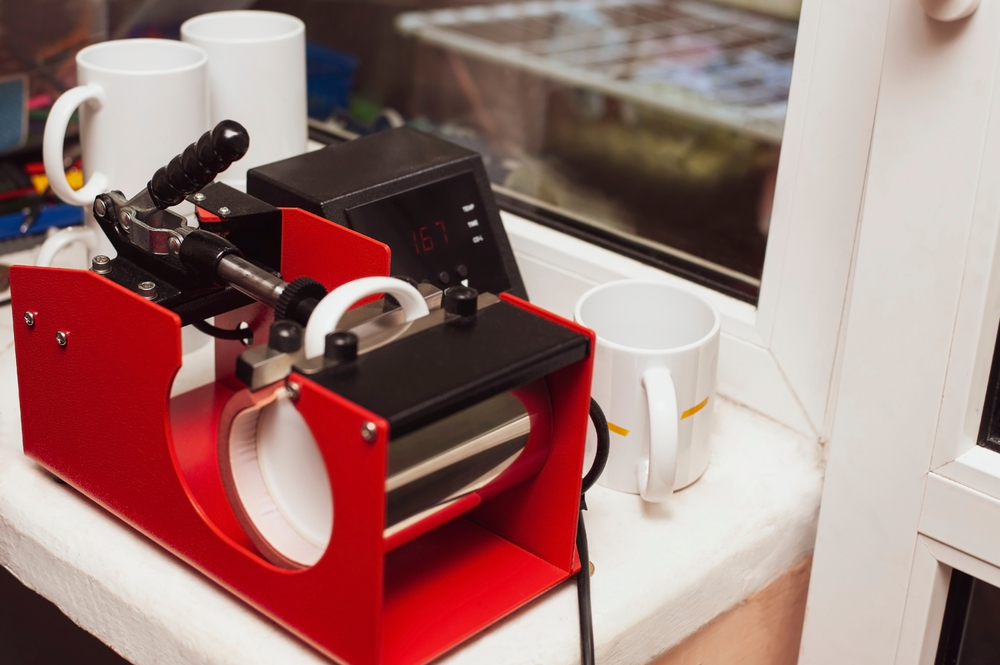

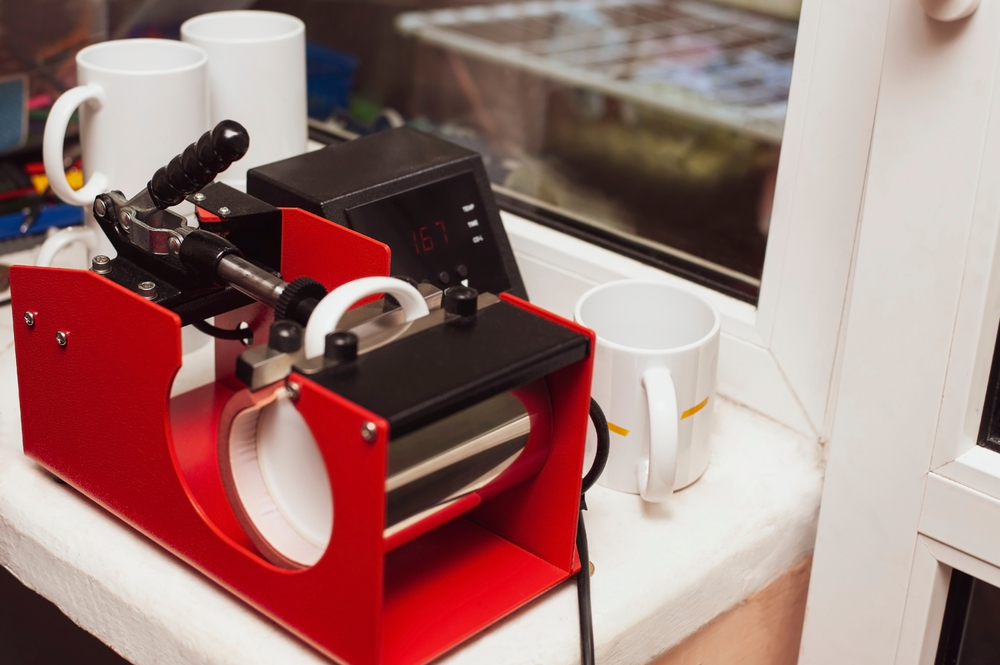

Heat Pressing

Heat pressing is a critical step in the sublimation process. The glass is subjected to high temperatures, typically between 350°F and 400°F (175°C and 205°C), for a specific period. The exact temperature and time can vary depending on the type of glass and the sublimation printer used. It’s essential to follow the manufacturer’s guidelines to achieve the best results.

Cooling and Finishing

After the heat press process, carefully remove the transfer paper from the glass. Allow the glass to cool completely before handling. Once cooled, you may need to clean the glass to remove any residue from the transfer paper.

Benefits of Sublimation Printing on Glass

Sublimation printing on glass offers several advantages over other printing methods:

- Vibrant Colors: Sublimation printing produces vibrant and vivid colors that are difficult to achieve with traditional printing methods. The ink permeates the glass surface, resulting in rich, high-quality prints.

- Durability: The sublimation process creates prints that are resistant to fading and scratching. The design becomes a part of the glass, ensuring that it will not peel or flake over time.

- Customizability: With sublimation printing, you can create highly customized designs, making it an excellent option for personalized gifts, promotional items, and decorative pieces.

- Versatility: Sublimation printing can be used on various types of glass surfaces, including glass coasters, photo frames, and even large glass panels.

Tips for Successful Sublimation Printing on Glass

- Choose the Right Glass: Not all glass surfaces are suitable for sublimation printing. Opt for specially coated sublimation glass or glass that has been treated to accept sublimation inks.

- Use High-Quality Sublimation Inks: The quality of the sublimation inks plays a significant role in the final print. Invest in high-quality inks to ensure vibrant and accurate colors.

- Proper Heat Settings: Follow the manufacturer’s recommended heat settings for your specific glass and sublimation printer. Incorrect temperatures can lead to poor-quality prints.

- Align the Transfer Paper Carefully: Proper alignment of the transfer paper is crucial for achieving accurate prints. Take your time to ensure the design is correctly positioned on the glass.

- Test Different Times and Temperatures: If you’re new to sublimation printing on glass, it may be helpful to test different times and temperatures to find the optimal settings for your specific materials.

Common Applications of Sublimation Printing on Glass

Personalized Gifts

Sublimation printing on glass is ideal for creating personalized gifts. Items such as photo frames, ornaments, and coasters can be customized with photographs or designs, making them perfect for special occasions like weddings, anniversaries, and birthdays.

Promotional Products

Businesses often use sublimation printing on glass for promotional products. Customized glassware, awards, and plaques can be printed with company logos and messages, making them effective marketing tools and corporate gifts.

Home Decor

Incorporating sublimation-printed glass into home decor is a growing trend. Custom glass panels, decorative items, and even glass countertops can feature unique designs and artwork, adding a personal touch to any space.

Conclusion

Sublimation printing on glass offers a remarkable way to create vivid, durable, and personalized items. By understanding the process, benefits, and tips for successful sublimation, you can unlock endless possibilities for customized glass products. Whether for personal use or promotional purposes, sublimation printing is a powerful tool for achieving beautiful and long-lasting designs.

Need a Printing Shop in San Diego, CA?

We here at 3 In 1 Design are a family-owned-and-operated custom print shop in San Diego, CA. We specialize in creating quality, screen-printed designs! Our in-house artist can create a special design based on your concept, or we can bring your own design to life if you’ve already got something made. We can print custom graphics on t-shirts, sweatshirts, school apparel, business cards, mugs, and much more. You tell us what you want, and we will make it happen! Call us today!